20th Nov 2024

£70K saved as heating energy load is HALVED!

The Refinery is a purpose-built student accommodation development in Leeds. It opened in 2021. A combination of studio and bedroom cluster flats accommodate 407 residents. Fresh Student Living manages the scheme on behalf of specialist investment company Curlew Capital.

Kristian Mills, Director of Asset Management at Curlew Capital is responsible for the mobilisation of properties and ensuring they are operated effectively.

He explains, “Over the first two of years of operation we found that we were spending more on utilities than we had expected for a property of this size. Students were able to override the programming on the heaters, turning them up to maximum and leaving them running continuously. To exacerbate the high use of electricity, windows would be opened and closed to regulate temperature. We were witnessing huge wastage. Costly in monetary terms, but as a company fully committed to its 2030 net-zero targets we needed to seriously consider this impact. One of the big things we identified, within our capability, is the control of energy for heating”.

Kristian sought to reduce this, “There were several solutions where sensors are placed in the bedrooms. They provide information on humidity, CO2, light etc. and had PIRs so you could monitor occupancy. But there weren’t many that controlled what was going on in individual rooms. I’ve been in student accommodation 20 years and have come across many heater panels with boosted control functions. I’d never come across anything where you can centrally control the heating system.”

Kristian discovered Prefect Controls. They were confident that Irus could sort the problem and return results promptly.

Irus is Prefect’s Building Energy Management System developed specifically for student accommodation. Control units in each room monitor conditions, and switch heaters on and off. The control units communicate with a central hub connected to the web based Irus Portal. Managers monitor and control individual rooms remotely.

Irus doesn’t restrict heating. It avoids unnecessary energy consumption: reducing heat input when rooms are unoccupied; windows are opened; and when occupants leave a room that’s in Boost state.

“There were three distinct factors that decided the deployment of Irus”, Kristian continues, “The availability of data on bedroom usage; Lowering of energy costs; and reduction of our carbon footprint.”

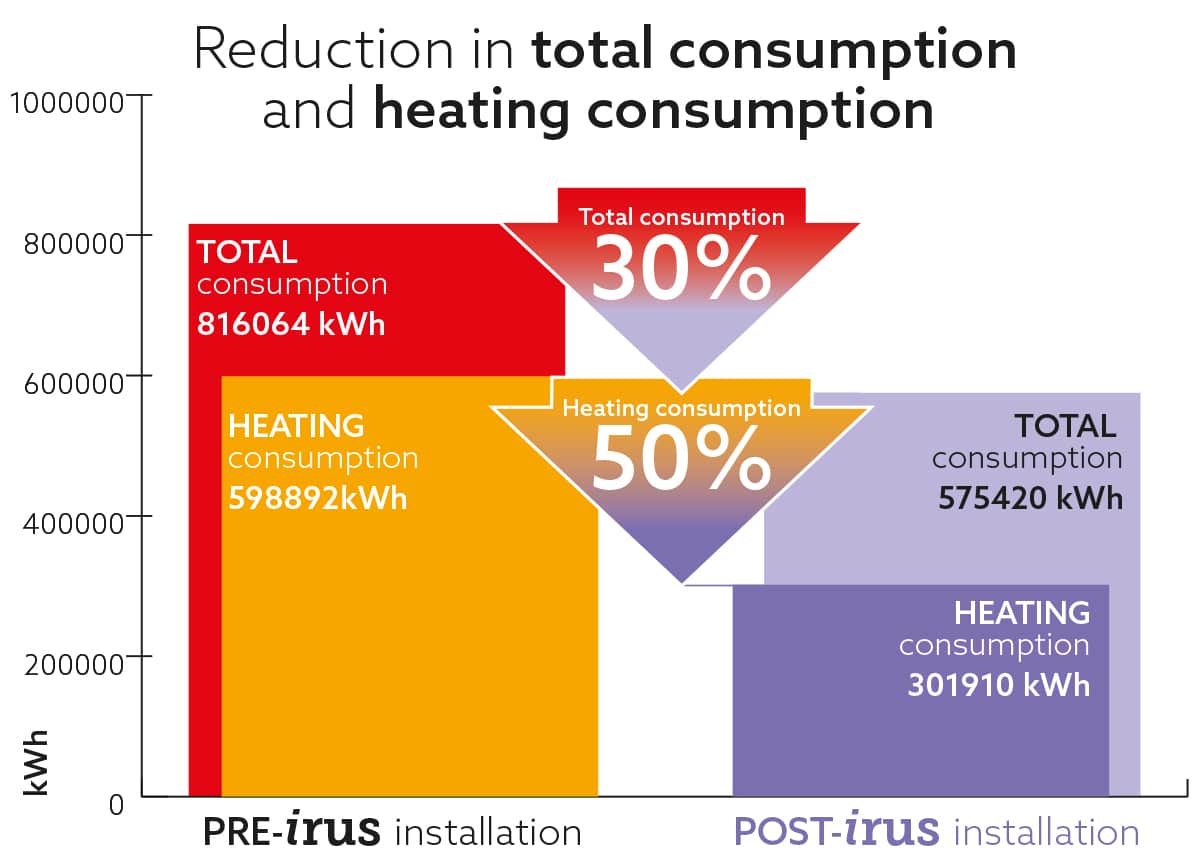

The first year’s performance is impressive.

• Heating energy halved 598,892kWh to 301,910kWh

• Total electricity 816,064kWh down to 575,420kWh

• Proportion of electricity for heating – 73% down to 52%

• 50% reduction per bedroom (1,464kwh to 738kWh)

• Almost £70,000 saved

The Head of Energy and Sustainability at Prefect has analysed the data. Gareth Chaplin explains, “Although first year figures are impressive, I can see potential for even greater savings. As operators familiarise themselves with Irus, there are tweaks to settings and profiles that will maximise performance.”

Kristian is clear about residents’ comfort, “It’s important to emphasise there is no restriction in the provision of heating for our guests. If residents need more warmth, managers can increase temperature, and lengthen boost times etc. It’s essential that residents are comfortable. But to run an efficient property and avoid waste, we must be able to monitor energy input and control delivery.”

He continues, “Going forward, we want to make Irus the standard specification for each property. We don’t want to have to retrofit heating systems, just make sure that the best possible system is installed, one that provides most information and control.

He concludes, “To see 50% reduction in heating load and close to £70,000 saved is phenomenal! We anticipate a return on investment of just over 3 years. These results highlight just how effective Irus has been.”

Manufacturing excellence

This is where EMS comes in. Having worked with Prefect Controls for 15 years, EMS has been involved from the onset in getting this product to where it is today.

EMS is an award-winning electronics manufacturing service provider based in Newbury, Berkshire. Founded in 2007, our teams specialise in surface mount technology (SMT) and printed circuit board assembly (PCBA) — using top-of-the-range equipment to deliver outstanding results every time.

We know that the current manufacturing industry isn’t exactly synonymous with sustainability. So, being passionate about our responsibility to protect the planet, we’re on a mission to change that and are proud to be involved in Irus.

And we’re not stopping there…

In an effort to develop an effective environmental management system and reach net-zero by 2050, EMS is working towards ISO 14001. This internationally recognised standard sets the criteria for formal climate impact reduction strategies and helps companies like us do our bit to help the planet.

Anyone attending Southern Manufacturing and Electronics 2025 can learn more about our services and sustainability commitments at our stand during the exhibition.

Back to News