Although surface-mount technology is more common nowadays, many PCBs use mixed technology. Rather than using solder to secure components onto the surface of the board, through-hole mounting involves placing components into drilled plated holes on a bare PCB.

Through-hole components are incredibly durable as they are soldered from both the top and bottom of the board — creating a strong physical bond. They also have a high environmental and power tolerance.

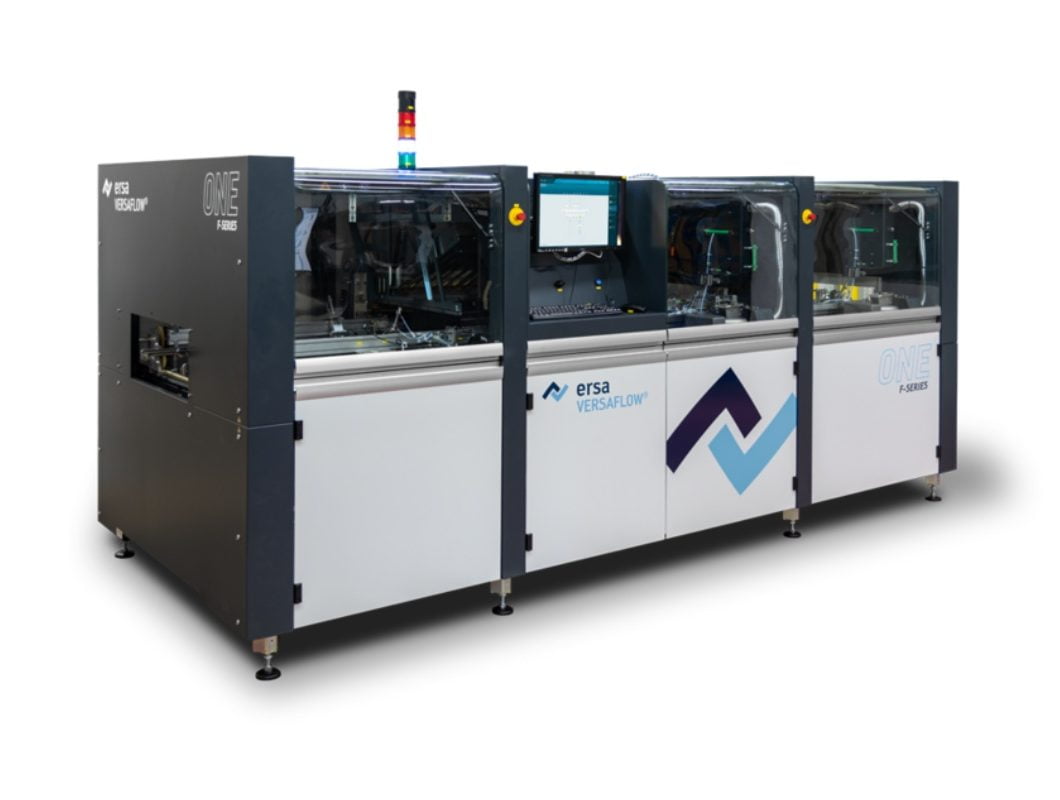

For the best results, a consistent selective soldering machine that offers flexibility is essential — which is why we’re excited to announce that our Kurtz Ersa Versaflow 3/35 Global Edition is now fully operational at EMSand ideal for a wide range of jobs (get in touch to find out if it’s suitable for your next project).

A reliable nitrogen supply is also crucial for selective soldering as it results in better wetting and clean joints with less flux and a lower temperature, so we’ve also added a new nitrogen generator system from Atlas Copco to our equipment.

As a specialist PCBA manufacturer, we believe investing in state-of-the-art equipment like this is vital to ensuring the accuracy and quality of all our electronics products. High-tech machinery allows us to refine each of our solutions to perfection and boost our production capabilities.