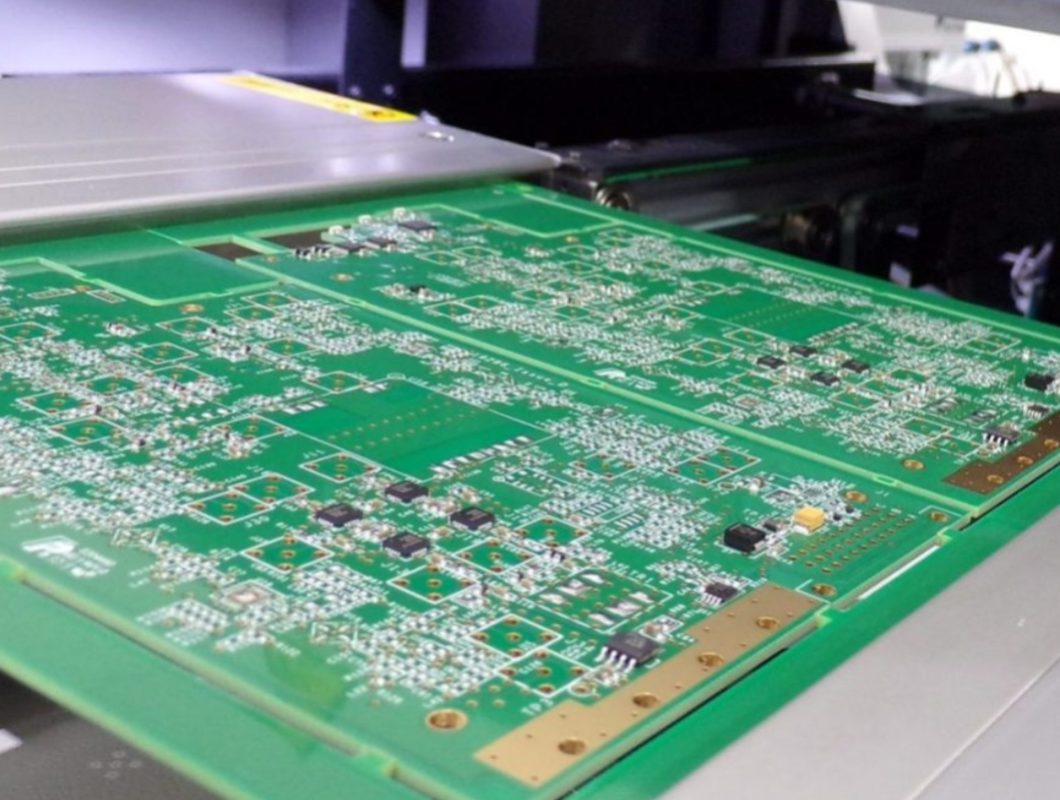

Surface-mount technology (SMT) is the most commonly used process in modern PCB design and assembly. The process involves directly securing components onto the surface of the board by solder, as opposed to placing them into drill holes like with through-hole mounting.

Surface-mount components are typically smaller in size — meaning more can be fitted onto tiny, complex boards. PCB assembly using this process is often faster and cheaper too, leading to cost savings for both the manufacturer and you, the customer.

Our machines use class-leading surface-mount technology, which offers optically aligned and flexible placement capabilities for all SMT component types including:

EMS offers, as standard, automated optical inspection (AOI) of all SMT components and production batches. This service includes component package recognition, part number check and solder joint inspection. Inspection is carried out to IP-A-610 Class 2 as standard, with Class 3 available on request.