PCBs play a crucial role in applications across many different sectors including consumer electronics, automotive, medical, telecommunications, military and defence, aerospace, lighting and security.

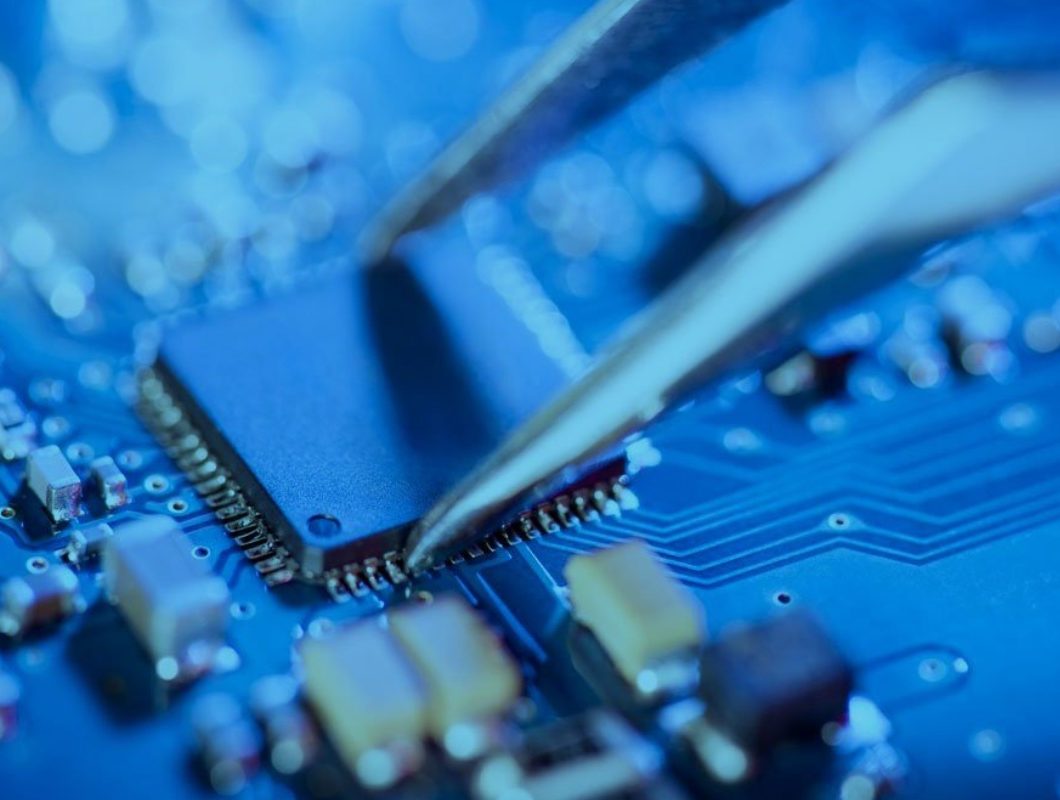

Over time, PCBs have evolved — allowing manufacturers to pack more functionality and complexity into smaller boards. Most boards today use a mix of plated through-hole technology (THT) and ultra-fine pitch surface-mount technology (SMT). Through-hole mounting involves placing components into drilled holes on a bare PCB, whereas components are secured by solder on the surface of the board in the SMT process.

As a specialist PCB assembly manufacturer, we offer both — enabling us to provide the complete assembly solution you require. Thanks to our policy of continuous investment, all of our PCB assembly services are carried out using the latest, top-of-the-range equipment.

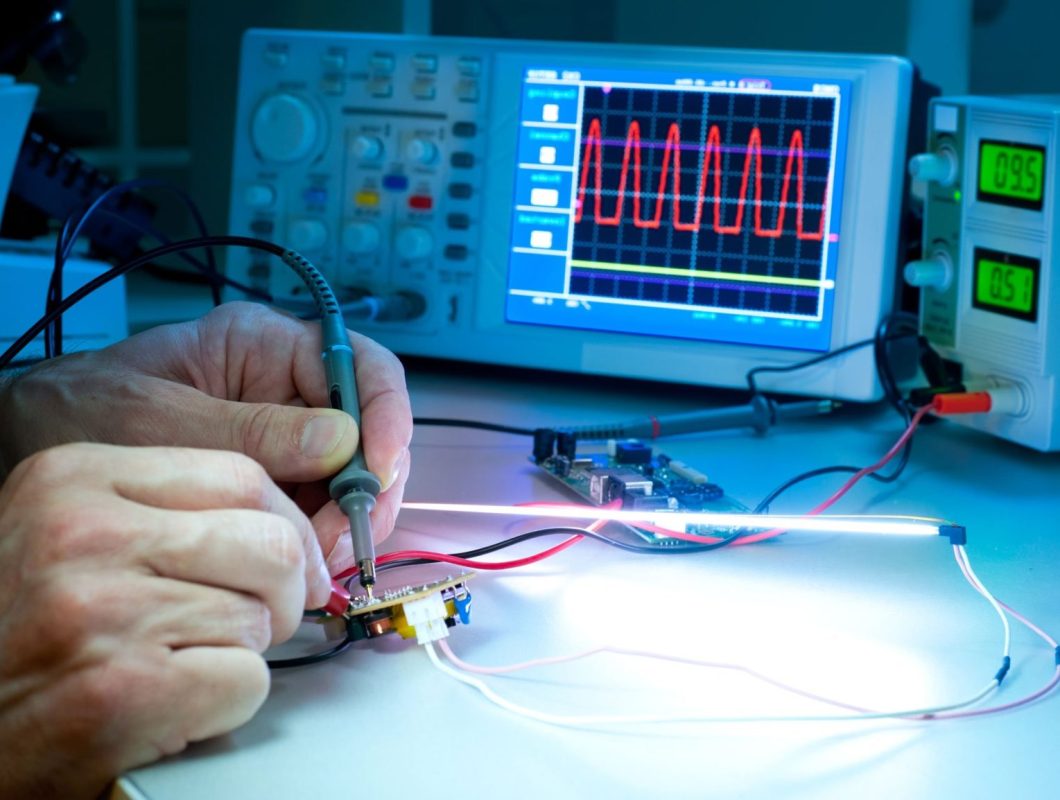

We supply PCB prototypes to volume. Our PCBA (printed circuit board assembly) prototyping services offer flexibility to suit any requirement and we will always adapt the solution offered to meet the target price, in line with the complexity and turnaround time.

EMS’ efficient prototyping can be combined with our quick turnaround service to deliver prototypes within 10 working days for standard designs.

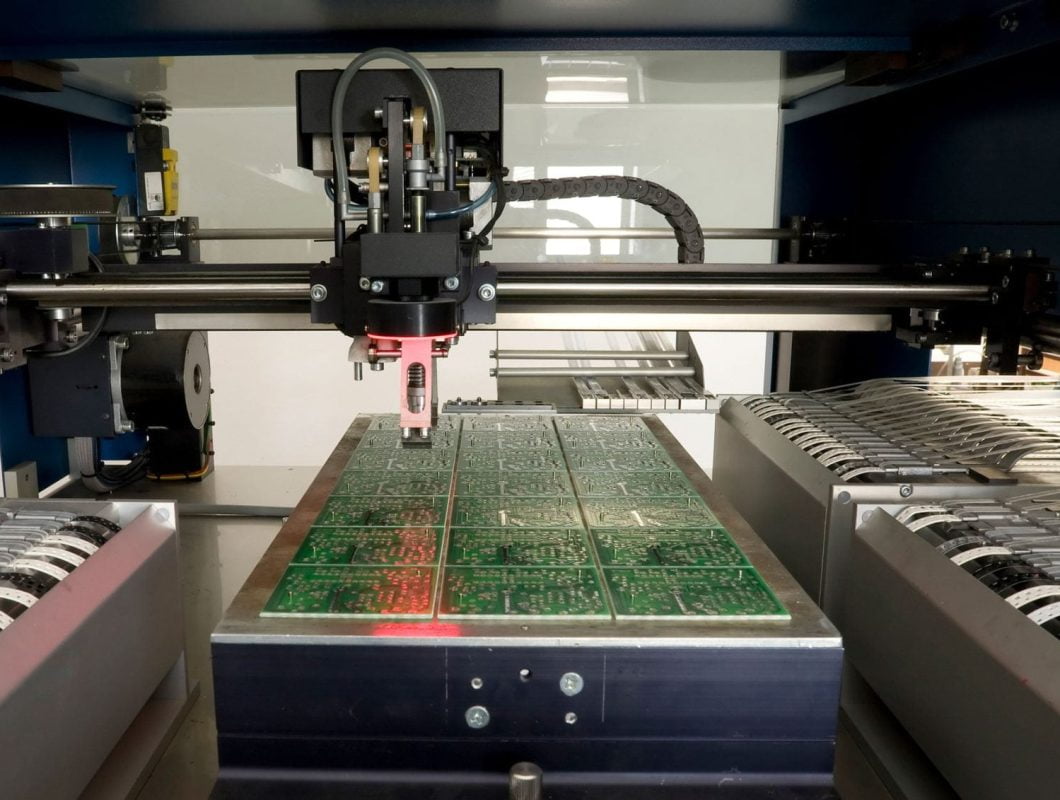

Our Trident ZDO Aqueous Cleaner is capable of adapting from low to high-volume batch production and contains adjustable board racks to handle PCBs up to 60mm in length for automatic wash, rinse and dry cycles.

The machine also features advanced statistical process control (SPC), data-logging with barcode scanner, built-in programmable cleanliness verification, testing via a resistivity meter and an automatic dosing and mixing system.